Waukesha

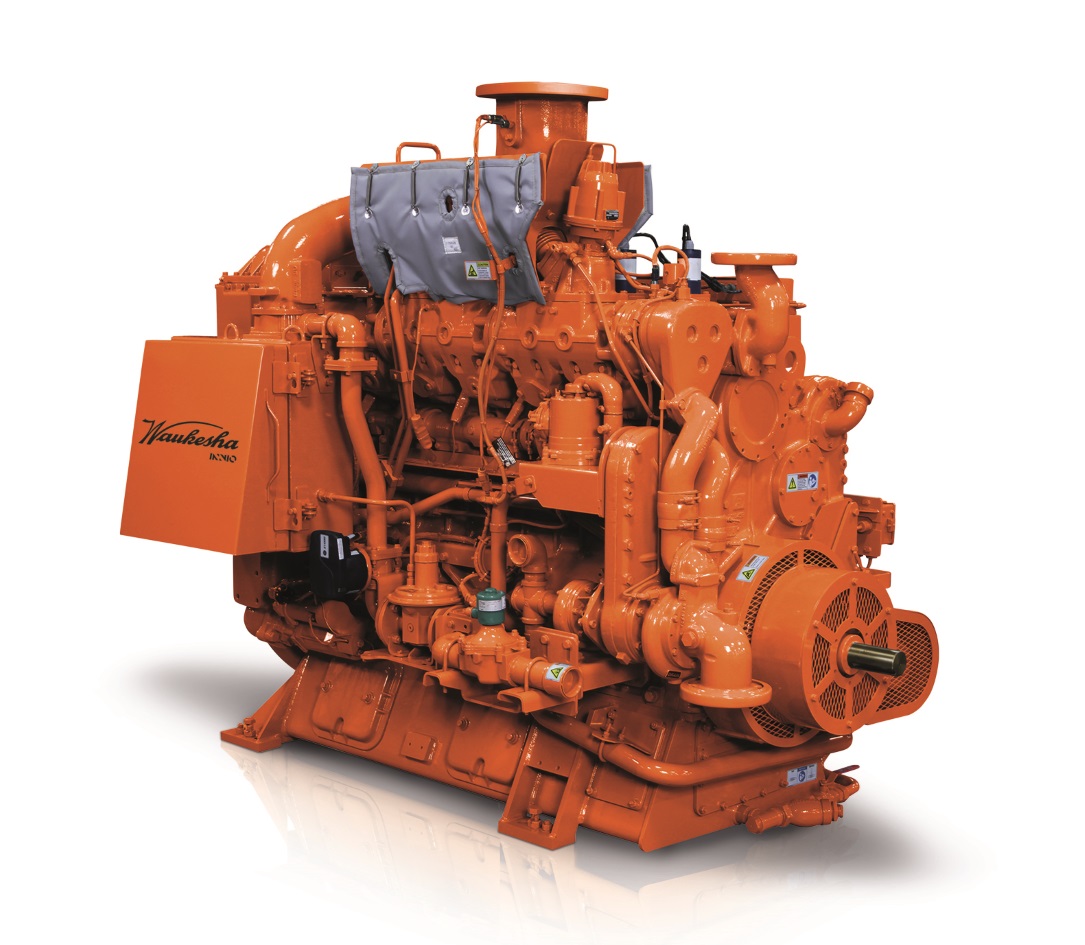

GAS ENGINE

Flexible and durable Waukesha* gas engines are designed to perform reliably in isolated, mission-critical and demanding applications. By offering both rich- and lean-burn designs, Waukesha provides a range of products covering varying emissions compliance levels to help you make smart choices for tomorrow.

Waukesha engines primarily are used in the oil and gas industries in applications such as gas compression, mechanical drive and power generation.

Known for their superior fuel gas flexibility, these engines operate on fuel gases from less than 200 BTU/ft3 all the way up to HD5 propane @ 2,350 BTU/ft3.

With rich-burn, lean-burn, turbocharged, naturally aspirated, high fuel gas pressure, low fuel gas pressure, low compression and high compression options available, Waukesha gas engines can be matched to each individual application.

Waukesha product portfolio

VGF*

- Electrical output: 200 – 830 kW

- L6, L8, V12, V16 cylinder

- 1,500 rpm (50 Hz), 1,800 rpm(60 Hz)

- Delivered engines: + 5,900 units

- Introduce in 1987

VHP*

- Electrical output: 540 – 1,600 kW

- L6, L12 and L16 cylinder

- 1,000 rpm (50 Hz), 1,200 rpm(60 Hz)

- Delivered engines: + 18,000 units

- 1967 – first VHP produced

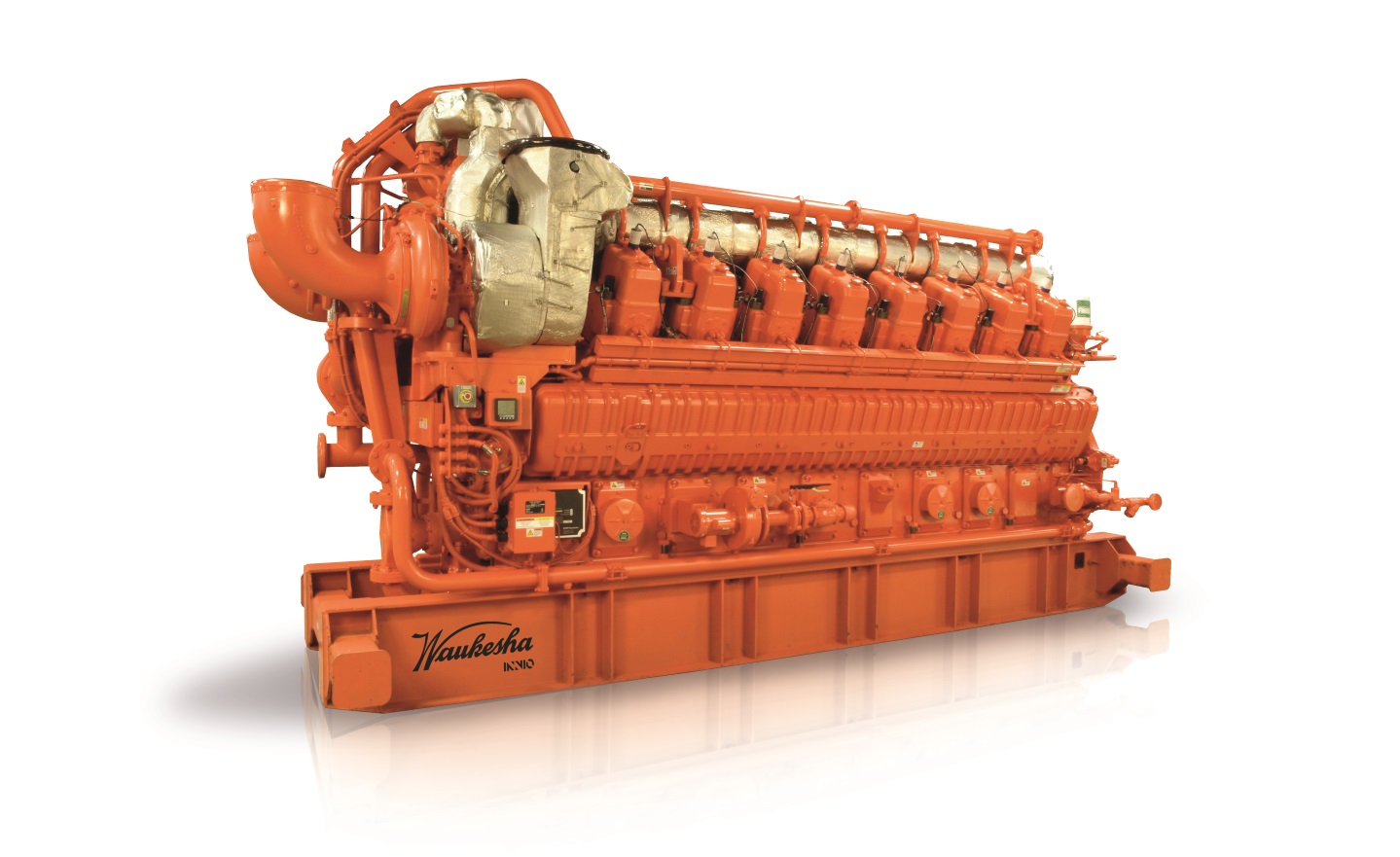

275GL+*

- Electrical output: 2,415 – 3,605 kW

- V12, V16 cylinder configurations

- 1,000 rpm (50 Hz), 900 rpm(60 Hz)

- Delivered engines: + 200 units

- Launched in 2009

ENGINE OVERHAULS

- All incoming engines are fully cleaned and inspected prior to a full stripdown.

- On completion of the inspection, a comprehensive report is issued to the customer, providing a full breakdown of all findings, component specifications and parts required to rebuild the engine to 100% condition.

ENGINE TEST FACILITIES

- Load test engines up to 1,200 kW / 1,600 hp

- Designed for testing the Waukesha VHP gas engine range, the facility includes a soundproofed control room for controlling and monitoring the engine during its testing.

- On completion of the test, a full report can be generated.

- Customers are invited to witness the engine testing

Inspection Report

- To ensure the customer is fully aware of the condition their engine was found in and to determine all parts required for the rebuild process are ordered correctly, a comprehensive inspection report is issued for each engine received for overhaul

Rebuild Report

- The rebuild report covers every stage of the rebuild and helps ensure the customer is aware of all steps carried out during the rebuild. The included engine test report confirms that the engine performs correctly and no problems will be found during startup at the customer’s site.

Location

333 Moo 5, Watprik, Muang, Phitsanulok 65230 Thailand.

Tel: (+66) (0)55 002 009

Fax: (+66) (0)55 002 017

Follow Us